Extras for Dock Levellers

Impact protection

Individual solutions for every area of application

Impact Protection Buffers 500 x 250 x 140 mm

- Vulcanized buffer made of virgin rubber

- Shore hardness: 75 ± 5

- Colour black

- Very stable design

- Also available as flat design with 90 mm in depth

Lining for Impact Protection Buffer

- Additional lining of the impact protection buffer, if there is a decline in front of the loading gate

- Can be retrofitted to existing buffers if required

Spring-Steel Buffers

- Spring-steel buffers especially offer protection during heavy goods loading in the process

of which great impact forces occur

- 620 x 180 x 145 mm

- 820 x 180 x 145 mm

Height-Adjustable Impact Protection Buffers, Vario Stop Type

Stop causing damage to buildings, gates and vehicles

- Vario-Stop safely stops interchangeable open bodies and extra-high trucks even for low ramp

heights.

- Also suitable for retrofitting of loading systems without dock levellers

- Do-it-yourself assembly is possible without difficulty

- Vario-Stop decelerates the vehicle. After docking, the Vario-Stop is brought back into its initial position by pressing it against a gas strut with the foot.

- The Vario-Stop does not hinder the loading process. After loading, the Vario-Stop is unlocked and automatically lifts itself driven by the gas strut, ready for the next vehicle.

Plug-in Buffers

- The inexpensive, mechanic alternative to Vario-Stop

- with 2 impact protection buffers 400 x 80 x 70 mm

- Vulcanized buffer made of virgin rubber

- Shore hardness: 75 ± 5

- Colour black

- Vulcanized-in metal sleeves and square washers

Impact Protection Buffers 500 x 80 x 100 mm

- Vulcanized buffer made of virgin rubber

- Shore hardness: 75 ± 5

- Colour black

- Vulcanized metal sleeves and square washers

Impact Protection Buffers 200 x 150 x 80 mm

- Vulcanized buffer made of virgin rubber

- Shore hardness: 75 ± 5

- Colour black

- Incorporated channel section washers fixed via 4 truss head screws

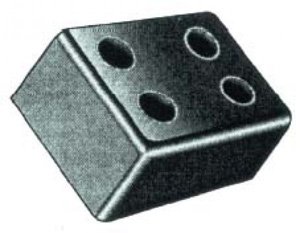

Delta Type Impact Protection Buffers

- Vulcanized buffer made of virgin rubber

- Shore hardness: 75 ± 5

- Colour black

- 2600 x 110 x 95 mm

Further Impact Protection Buffers Upon Request...

Door End Switches

Extras for Dock Levellers

For your new and old dock levellers we also offer the corresponding extras. Rubber buffers, docking buffers or impact protection buffers for your dock levellers are also part of our product range as are replacement parts for dock levellers. Replacement parts comprise sealings, docking protection equipment, safety plates and also individual steel segments to be replaced in defect dock levellers.

Rubber buffers are important to maintain your dock levellers as well as the building. In the event of a strong shock, the approaching trucks might damage the bricking or even the loading space itself. Thanks to the buffer, the impact is absorbed and there is no need to worry about technical equipment. These simple safety measures result in large money-savings. You will only invest a small sum, however you will save much money since your equipment will not suffer any damage anymore. Thanks to this principle you will easily contribute to the long-term success of your company and you will offer a safe and fully functional environment to your staff.

As your supplier of dock levellers and dock shelters we offer to help you find the suitable loading systems and accessories for your company. For any questions and requests, please contact one of our staff members to get a comprehensive consultation. We will equip you with everything required for a successful loading company and we will help you to keep your storage and loading technology up-to-date.