CKL/QKL Hinged Lip Dock Levellers

Electro-hydraulic dock levellers with hinged lip

Constructive Design

The platform of the hinged lip dock leveller consists of a raised pattern plate, 8 mm thick (anti-slip). Beneath it, welded enforcements increase its load bearing capacity. For the load bearing tests, we assumed the worst case (= lumped load). Within the frame, the platform is easily replaceable. As an option, independently of the dock leveller, the front frame may also be encased in concrete in the first place. After corresponding progress of construction to place, the platform may easily be inserted and then immediately is ready to operate. The low design height and the self-supporting construction of the frame allow for the truck tailboards to be driven beneath the hinged lip. The welding is done by certified welders being supervised by welding engineers. A continuous quality control ensures the high and consistent dock leveller quality.

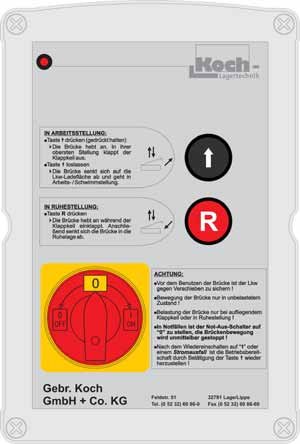

Control System

The micro-processor control system is designed to be easily customized. It is relatively easy to add functional extensions such as dock shelter/dock leveller locks, integrated dock leveller control or the like.

Control System Standards

- Automatic return to its rest position

- Work restart inhibit after triggering the emergency tripping device

- Standstill during voltage drop

- IP54 degree of protection in accordance with DIN 40050

Hydraulics

The dock leveller is lifted and lowered by 2 hydraulic jacks that are in floating position during the loading process. Burst pipe protection valves in the hydraulic jacks ensure a safety stop in case of emergency. The extendable lip is extended by means of a double acting cylinder so that the desired extended position will be reached precisely. The hydraulics unit with its compact design may also be operated using biodegradable hydraulics oil.

Safety

- Non-stop in each working position

- Special stability in case of emergency thanks to the usage of 2 hydraulic jacks

- If the truck accidentally rolls away under heavy load, the dock leveller stays in its current position

- Protective side shrouds (8 mm thick) with yellow-black hazard marks.

- Inspection bolts

The entire design is in accordance with regulation BGR 233 (latest edition) for dock levellers and movable ramps, with series type certificate.

Dock Levellers With Hinged Lips

A hinged lip dock leveller provides you with a reliable loading system, which enables you to handle things safely and conveniently. It is easy to operate the hinged lip dock leveller. Dock levellers can be safely lowered onto the truck's cargo area applying electro-hydraulics. In the electro-hydraulic version, at the push of a button the hinged lip dock leveller rises to the highest position at which the lip is then extended. After letting go of the control, the dock leveller lowers itself to rest on the cargo space floor. For the purpose of maintenance work, the hinged lip dock leveller may be held by a maintenance strut in order to prevent serious accidents. For more slender trucks, the lateral swing segments may also be lowered separately. In this way dock levellers can rest in an accurately fitting way. These and further parts out of the Koch Lagertechnik product range may help to make daily routine much easier in your warehouses. Thanks to a smooth work process when using dock levellers much time is saved and thus much money is saved in the long run.

As supplier of dock levellers we ensure safety in and around your warehouses so that your un-/loading procedures will be handled quickly and securely. Safe loading systems guarantee reliable working conditions and continuously efficient work performed by your staff. Should you like to know more about dock levellers, please do not hesitate to contact us. Special equipments and on-site assembly service also are part of the services we offer. In this way we hope to make it easer for you to start applying more efficient warehouse equipment or to maintain already existing warehouse equipment.